Designing your own circuit board can be an exciting and rewarding journey. In 2022, the global PCB market reached a whopping $74.2 billion, showcasing the industry's growth potential. More individuals are turning to DIY electronics, driven by innovation and education. The ability to design your own circuit board empowers creators and hobbyists alike.

However, venturing into the world of circuit board design comes with challenges. Beginners often face steep learning curves. It's crucial to grasp fundamental concepts like schematic design and layout techniques. Resources are available, but not all are user-friendly. Mistakes in design can lead to functional failures, prompting the need for iterative improvements. Many makers find that trial and error is part of the learning process.

Embracing this complexity makes the journey worthwhile. Each circuit board designed is a step toward mastery and creativity. Enthusiasts often share their experiences, highlighting both successes and setbacks. The circuit board you create could be a tool for innovation or simply a fun project. Regardless, the skills gained are invaluable. Design your own circuit board and explore the endless possibilities of electronics.

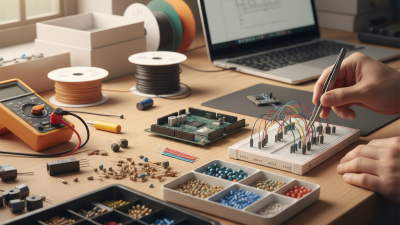

Designing a circuit board can seem daunting, but understanding the basics can simplify the process. Begin with your concept. Sketch out your idea on paper. This helps visualize circuit connections. Identify components like resistors and capacitors. Each plays a crucial role in your design.

Next, use software to create a layout. A digital tool can streamline this step. Ensure your connections are clear. It's easy to overlook connections, leading to potential issues. Check the spacing between traces. Sufficient gaps prevent short circuits and signal interference.

After drafting your board, it's time to reflect. Mistakes happen in every design. Perhaps a component doesn't fit as planned. You might realize certain connections are too close. Learning from these challenges is key. Every iteration improves your skills. Embrace the trial-and-error process in your journey.

This bar chart represents the number of basic components typically used in circuit board design. Understanding these components is essential for beginners in electronics and circuit board design, as they form the building blocks of any circuit.

When designing a circuit board, choosing the right tools and software is crucial. Many beginners overlook this step. A survey by the IPC shows that over 70% of engineers believe that quality PCB design tools improve productivity. Selecting intuitive software can make the learning curve less steep.

Many tools offer features like schematic capture and simulation. A good option is software that provides real-time collaboration. This is an emerging trend in the industry. The 2022 PCB Design Software Report revealed that 80% of users notice faster iterations with such tools. Don’t settle for software that feels clunky or outdated.

Tip: Start with free or trial versions of software. This allows you to explore different tools without a financial commitment. Evaluate how user-friendly they are. Invest time in tutorials, as they can shorten your learning curve significantly. Also, consider community support. Platforms with active forums can be invaluable for troubleshooting.

Creating a schematic diagram is a critical step in designing your own circuit board. A schematic serves as a visual representation of your circuit's components and their connections. It is essential to establish a clear layout early on. Misplaced components can lead to confusion and faulty designs. According to a report by the Electronic Industries Alliance, nearly 30% of design flaws come from initial schematic errors.

When you draft your schematic, ensure all symbols are correct. Each component should be labeled clearly. This clarity helps when you later translate the schematic into a physical circuit board. Industry standards emphasize the importance of following rules for connections and component placement. For instance, using standard symbols makes the schematic universally understandable. Overlooking this can result in misunderstandings, especially in collaborative projects.

It's also important to review your schematic thoroughly. Check the connections multiple times. An overlooked mistake can lead to a non-functional circuit. A study from the IEEE shows that approximately 25% of circuit design failures are caused by poor documentation. Take the time to reflect on your work before moving on to the next stages of circuit design. Every detail counts. Mistakes can offer valuable learning opportunities. By refining your schematic, you build a solid foundation for your project.

Translating schematics into a PCB layout is a crucial step for beginners. This transition can often be daunting. A recent report states that nearly 40% of novice designers struggle with this phase. Understanding the fundamentals of schematic representation is essential. Each component connects logically in the schematic. However, in a PCB layout, practical spacing and routing must be considered.

When laying out your PCB, think about component placement carefully. It’s not merely about fitting parts on a board. Noise, thermal management, and signal integrity play significant roles. Research shows that 50% of PCB failures arise from inadequate placement and routing. For instance, keeping high-frequency traces short can minimize interference.

Reflections on the process are important. Many learners find it challenging to balance aesthetics with functionality. Every design has imperfections. It’s common to discover an error too late. Reviewing and revising the layout can lead to improvement. Take time to iterate the design, ensuring all connections are valid. Embrace this trial-and-error nature; it’s part of becoming proficient in PCB design.

| Step | Description | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Understand basic electronic components and circuit theory. | Books, Online Courses | 1-2 weeks |

| 2 | Create a circuit schematic using design software. | CAD Software (e.g., Eagle, KiCad) | 3-4 days |

| 3 | Translate the schematic into a PCB layout. | PCB Design Software | 2-3 days |

| 4 | Review and verify the design for errors. | Peer Review Tools | 1-2 days |

| 5 | Order the PCB from a manufacturer. | Online PCB Service | 1 week |

| 6 | Assemble components onto the PCB. | Soldering Iron, Components | 1-2 days |

| 7 | Test the assembled circuit. | Multimeter, Power Supply | 1 day |

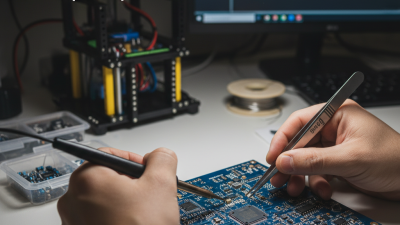

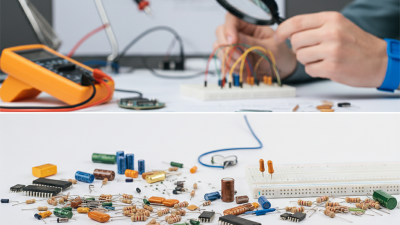

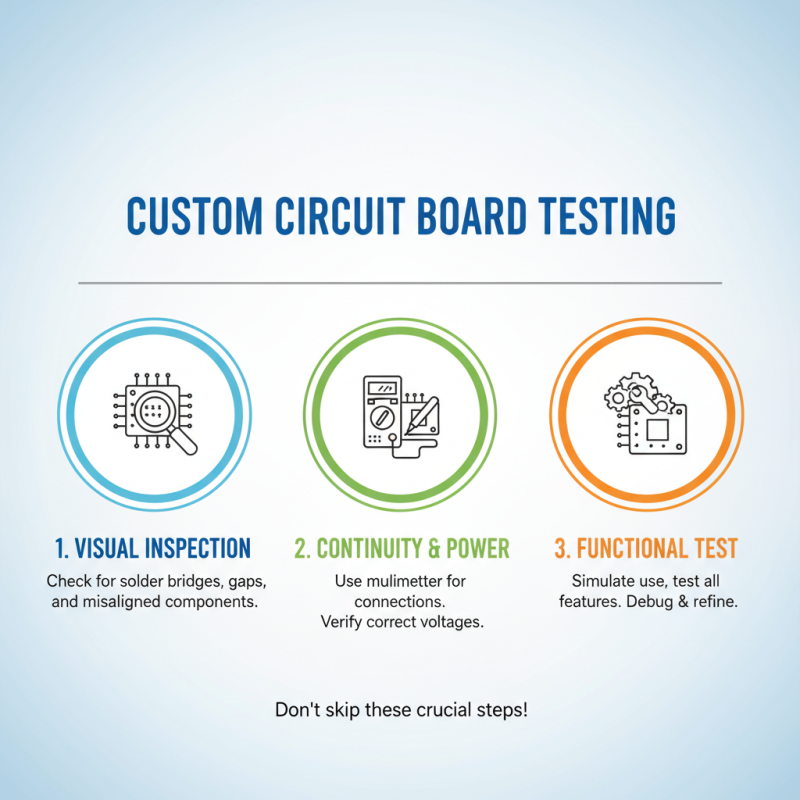

Testing your custom circuit board is a crucial step. After designing your layout, you need to verify that everything works. Begin with a visual inspection. Look for any obvious mistakes. Check for solder bridges or gaps. These small errors can cause big issues. Utilize a multimeter to test connections. Make sure the correct voltages appear at the right points. It's common to miss a connection or misplace a component.

Fabricating your circuit board requires planning. Start by choosing the right materials and technology. You can use a simple PCB etching method at home. Follow the manufacturer’s instructions carefully. This process can produce errors if rushed. If you opt for professional services, understand their specs. Allow time for revisions; this reduces mistakes. Mistakes in fabricating can lead to wasted time.

After testing and fabricating, assembly follows. This part can be challenging. Placing components in the correct orientation is crucial. Some components may be difficult to fit. Reflections on your design will help you improve. Document any issues you encounter during assembly. This feedback is valuable for future projects. Embrace the learning process.