When embarking on an electronics project, one of the most critical decisions you will face is selecting the right electronic assembly equipment. The complexity of modern electronics, coupled with the diverse range of available technologies, can make this task daunting. Choosing the appropriate equipment is essential not only for enhancing the efficiency of the assembly process but also for ensuring that the final product meets quality and performance standards. With a myriad of options available—from soldering stations and pick-and-place machines to testing equipment—understanding the specific needs of your project is paramount.

In this guide, we will explore the key factors to consider when selecting electronic assembly equipment. We will discuss the importance of assessing your project's scale, budget, and specific requirements to help you make an informed choice. By evaluating aspects such as production volume, component types, and required precision, you can streamline the assembly process, reduce costs, and ultimately achieve a successful outcome. Whether you are a seasoned professional or a novice tackling your first project, this overview will provide valuable insights into making the best equipment selections to suit your electronic assembly needs.

When embarking on an electronic assembly project, choosing the right equipment is crucial for ensuring efficiency and quality. Understanding the various types of electronic assembly equipment can help streamline this process. The most commonly used equipment includes pick-and-place machines, soldering stations, and reflow ovens. Pick-and-place machines are essential for accurately placing components on printed circuit boards (PCBs) with precision, which increases assembly speed and reduces manual errors. In contrast, soldering stations are indispensable for connecting components securely, offering different soldering techniques like wave soldering and selective soldering to accommodate various project requirements.

Additionally, reflow ovens play a critical role in the soldering process by melting solder paste and creating reliable joints. These ovens utilize temperature profiles that ensure even heating and cooling to prevent damage to sensitive components. Other important tools include inspection equipment, like automated optical inspection systems, which detect defects during production. The selection of electronic assembly equipment depends on several factors, including production volume, complexity of the assembly, and available space. By carefully analyzing these options, one can determine the best setup for their specific project needs, leading to a successful electronic assembly process.

| Equipment Type | Key Features | Ideal Use Cases | Price Range |

|---|---|---|---|

| Pick and Place Machine | High precision, automated component placement | High-volume production, PCB assembly | $15,000 - $90,000 |

| Soldering Station | Temperature control, interchangeable tips | Prototype assembly, repair work | $50 - $500 |

| Reflow Oven | Temperature profiles, batch processing | Mass production, soldering of surface mount devices | $5,000 - $30,000 |

| Wave Soldering Machine | Consistent solder joint quality, through-hole component support | Complex PCB assemblies with through-hole components | $20,000 - $100,000 |

| Automatic Optical Inspection (AOI) System | High-resolution imaging, defect detection | Quality control, defect inspection during production | $10,000 - $50,000 |

When embarking on an electronic assembly project, evaluating your project's specific requirements is critical in selecting the right equipment. Begin by understanding the scale and complexity of your project. Will you be working on small-scale prototypes or large-volume production? For instance, high-volume production may necessitate automated equipment to enhance efficiency and reduce labor costs, whereas smaller projects might benefit from more flexible manual assembly tools, allowing for intricate work without the need for substantial investments.

Next, consider the types of components you will be assembling. Different electronic components, such as surface mount devices (SMDs) or through-hole components, require different assembly techniques and tools. Assess whether your assembly process will involve soldering, pick-and-place operations, or testing, and ensure the equipment you're considering can accommodate these needs. Additionally, think about the necessary precision and quality requirements, as this will influence whether you need high-precision machines or standard tools. By thoroughly assessing these project requirements, you can make informed decisions that will ultimately streamline your assembly process and enhance the quality of your end product.

When selecting electronic assembly equipment for your project, it is crucial to evaluate the key features and specifications that align with your specific needs. Consider the technology involved, such as through-hole versus surface mount assembly, as each presents unique advantages depending on the complexity of your circuit designs. The speed and efficiency of the equipment can significantly affect your production timelines, so be sure to explore options with suitable throughput rates and cycle times.

Tips: Always analyze the compatibility of the equipment with your existing processes. If you have a mixed-technology environment, ensure that the assembly equipment can handle various component types effectively. Additionally, look for equipment with user-friendly interfaces, which can mitigate training time and enhance productivity right from the start.

Another important aspect is the equipment's precision and reliability. Specifications such as placement accuracy and soldering techniques should be scrutinized to ensure they meet the standards necessary for your project quality requirements. Moreover, assessing maintenance needs and support services available can impact long-term operational efficiency, making it essential to factor these into your decision-making process.

Tips: Do not overlook the importance of scalability; choose equipment that can support future expansions or modifications to accommodate new tech trends or increased production demands. Make a checklist of must-have specifications and features that are critical to your success.

When selecting electronic assembly equipment for your project, cost-effectiveness plays a crucial role in the decision-making process. Different assembly solutions come with varying price tags, and understanding their value in relation to your project requirements is essential. For instance, manual assembly can be less expensive initially but may lead to higher labor costs over time, especially for larger production runs. On the other hand, automated systems involve larger upfront investments but can reduce long-term operational costs by increasing efficiency and minimizing errors.

Tips: When assessing the cost-effectiveness of assembly solutions, consider the total cost of ownership (TCO). This includes not only the initial purchase price but also maintenance, tooling, and labor costs. Additionally, evaluate the speed and scalability of each option. Sometimes, investing in a more advanced system can yield better returns over time by enabling quicker production rates and a higher output.

Furthermore, aligning the assembly solution with your project’s specific needs can enhance overall cost-effectiveness. Assess the complexity of your product and the required volume; this will help you determine whether a flexible, low-volume solution or a high-speed, high-volume system is more appropriate. Ultimately, making informed choices that align with both your budget and project requirements will enhance profitability and efficiency in the long run.

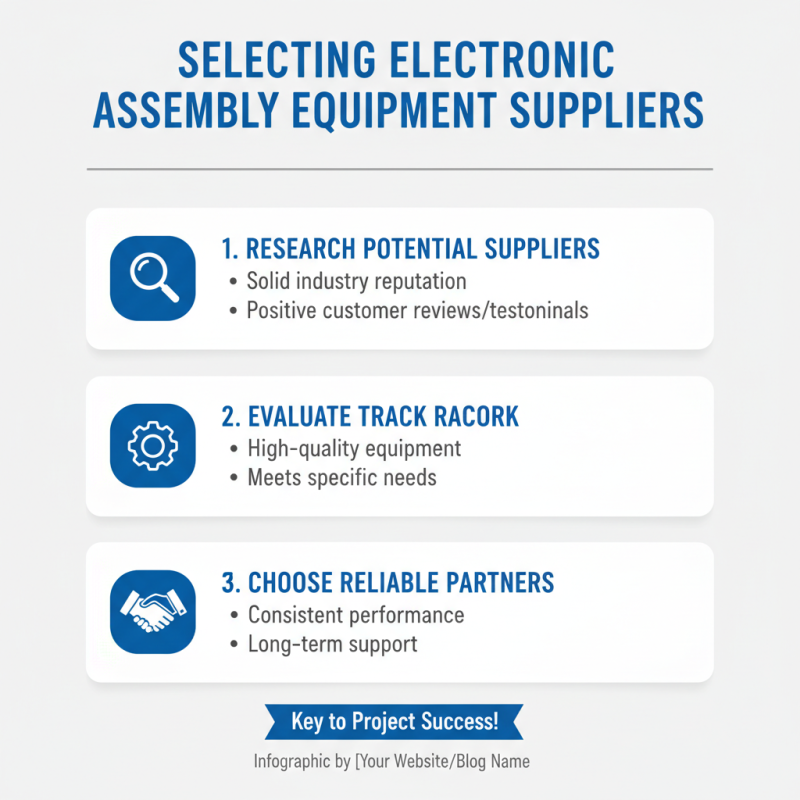

When selecting electronic assembly equipment for your project, identifying reliable suppliers and manufacturers is crucial. The first step is to research potential suppliers thoroughly. Look for companies with a solid reputation in the industry, backed by positive customer reviews and testimonials. Consider their track record in providing high-quality equipment that meets your specific needs.

Tips: Always verify the supplier's certifications and compliance with industry standards. A good supplier should have relevant certifications that demonstrate their commitment to quality and safety. Don't hesitate to ask for references from previous clients, as their experiences can offer valuable insights into the supplier’s reliability and product performance.

Another essential aspect is to assess the supplier’s customer service and support. A reliable manufacturer should provide timely assistance and be willing to address any concerns during the purchasing process and beyond. This support can include training on how to use the equipment effectively and assistance with troubleshooting or repairs if needed.

Tips: Initiate contact with potential suppliers to gauge their responsiveness and willingness to assist. This interaction can reveal much about their customer service approach and their dedication to fostering long-term relationships with clients. The right partner will not only sell you equipment but will be invested in your project's success.