In the ever-evolving world of manufacturing, the selection of electronic assembly equipment can greatly influence both product quality and operational efficiency. According to Dr. Emily Chen, a leading expert in the field of electronic manufacturing technologies, "Choosing the right electronic assembly equipment is not just about functionality; it's about ensuring long-term reliability and precision." This insight emphasizes the critical nature of making informed decisions when it comes to investing in the right tools and machinery.

As businesses face increasing pressures to improve production speed and reduce costs, the right electronic assembly equipment can serve as a cornerstone for achieving these goals. With a plethora of options available in the market, understanding the specific needs of your operation becomes essential. From automated surface mount technology (SMT) machines to specialized soldering tools, each piece of equipment plays a role in the seamless flow of the assembly process.

Navigating this landscape requires a careful assessment of factors such as production volume, product complexity, and budget constraints. By focusing on these elements and leveraging expert insights, manufacturers can tailor their equipment choices to enhance productivity and ensure top-tier product quality. Ultimately, making the right investment in electronic assembly equipment can set the stage for sustained success in a competitive market.

When selecting electronic assembly equipment, it’s vital to begin with a clear understanding of your specific requirements. Each project can vary significantly based on factors such as volume, component size, and complexity of the assembly. For high-volume production, seeking equipment that can handle rapid assembly speeds and automation capabilities becomes paramount. Conversely, for smaller batches or prototypes, flexible equipment that accommodates various configurations might be more suitable. Identifying these operational parameters upfront will streamline the decision-making process and lead to more effective use of resources.

Furthermore, consider the types of components you will be working with, as this greatly influences the selection of assembly equipment. Fine-pitch components may necessitate more advanced pick-and-place machines, while through-hole components could be best served with equipment designed for traditional soldering methods. Additionally, think about any special handling needs your components may have, such as ESDS protection or unique accommodation for fragile parts. By mapping out your specific assembly needs, you can ensure that you choose the right equipment that not only meets your current demands but also adapts to potential future projects. This tailored approach will enhance overall production efficiency and quality.

When selecting electronic assembly equipment, it is crucial to identify key features that align with your operational needs. A recent industry report highlights that 70% of businesses prioritize equipment versatility, enabling them to handle various types of assembly tasks. This adaptability is vital in a landscape where production demands fluctuate and the ability to pivot quickly can give companies a competitive edge.

Another essential feature to consider is the equipment's automation capabilities. According to a study by the Automation Industry Association, automated assembly lines can boost production efficiency by as much as 30%, while reducing error rates significantly. Features such as intelligent vision systems and programmable logic controllers (PLCs) are becoming standard, enabling manufacturers to enhance accuracy and speed while lowering labor costs. Investing in equipment with such advanced technologies can not only improve production metrics but also streamline processes for future scalability, thus ensuring long-term growth and adaptation in a fast-evolving market.

When selecting electronic assembly equipment, understanding the various types of tools available is crucial for making an informed decision. The primary categories include hand tools, automated assembly machines, and inspection equipment. Hand tools, such as soldering irons and wire strippers, are essential for small-scale projects or prototyping. They offer flexibility and precision, making them ideal for tasks that require manual dexterity. These tools are typically more affordable and user-friendly, catering to hobbyists and small workshops.

Automated assembly machines, on the other hand, are suited for larger production runs and offer efficiency and consistency. Options like pick-and-place machines and wave soldering machines streamline the assembly process, significantly reducing labor costs and lead times. While the initial investment in automated equipment can be higher, the long-term savings and increased output often justify the expense for larger manufacturers.

Additionally, inspection equipment, including AOI (Automated Optical Inspection) and X-ray machines, plays a vital role in ensuring quality control throughout the assembly process. These tools help identify defects and verify assembly accuracy, which is critical in maintaining product reliability. Balancing the needs of your operation with the capabilities of each type of assembly tool will lead to better outcomes in your electronic assembly projects.

| Tool Type | Key Features | Typical Uses | Advantages | Disadvantages |

|---|---|---|---|---|

| Soldering Iron | Variable temperature control, fine tip | Soldering components to PCB | Versatile, portable | Requires skill, can damage parts if not used properly |

| Reflow Oven | Programmable heating zones, conveyor belt | SMD soldering | Consistent soldering results, efficient for high volume | Expensive, requires space |

| Pick and Place Machine | Automated component placement, camera alignment | Automated PCB assembly | High speed, precise placement | High initial cost, complex setup |

| Multimeter | Voltage, current, resistance measurements | Troubleshooting and testing | Essential for diagnostics, easy to use | Limited to electrical measurements |

| PCB Etching Kit | Chemical etching solution, copper boards | DIY PCB fabrication | Cost-effective for prototyping | Messy, requires safety precautions |

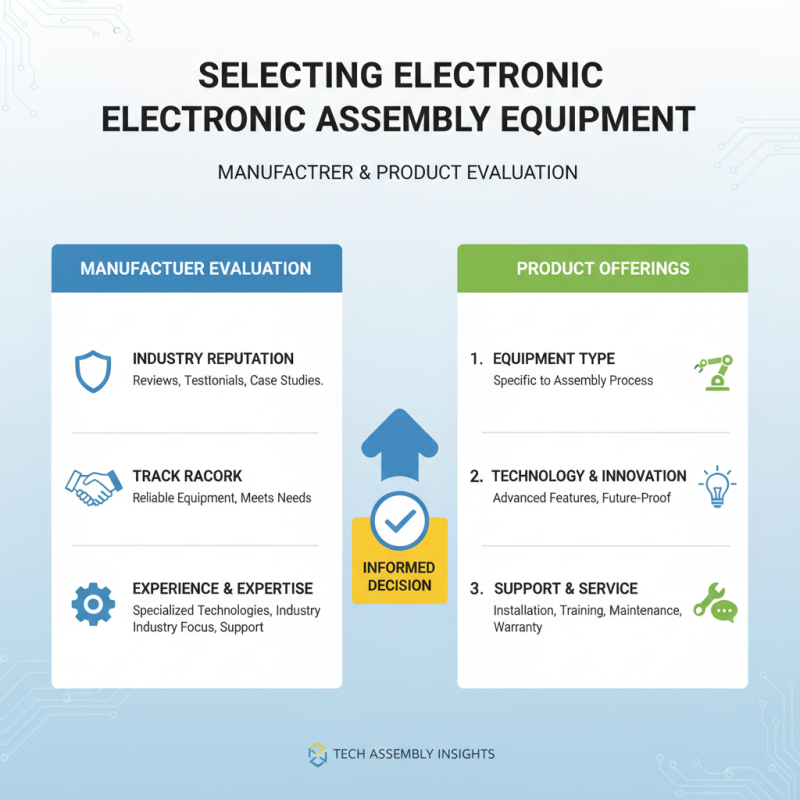

When selecting electronic assembly equipment, evaluating manufacturers and their product offerings is crucial. Start by researching the reputation of potential manufacturers in the industry. Look for reviews, testimonials, and case studies that highlight their strengths and weaknesses. A manufacturer with a solid track record is more likely to provide reliable equipment that meets the specific needs of your assembly process. Additionally, consider their experience and expertise in the type of equipment you require. Manufacturers that specialize in particular technologies or industries may offer better insights and support.

Next, examine the range of products offered by each manufacturer. A diverse product line indicates a company’s capability to meet various assembly requirements. Investigate the specifications of each piece of equipment to ensure they align with your production goals. Factors such as automation capabilities, ease of integration, and scalability should be prioritized to support your business's growth. Furthermore, consider the availability of parts and technical support, as ongoing maintenance is vital for uninterrupted operations. By thoroughly evaluating manufacturers and their products, you can make a well-informed decision that optimizes your electronic assembly operations.

When budgeting for electronic assembly equipment, the first step is to clearly define your operational requirements. Analyzing the specific needs of your production line will help you determine the necessary features and capabilities of the equipment. Consider factors such as production volume, complexity of assemblies, and future scalability. These elements will guide you in identifying the right type of machinery that aligns with your operational goals while avoiding unnecessary expenditures on features that do not serve your current needs.

Next, it's crucial to factor in not only the upfront cost of the equipment but also the long-term operational expenses. This includes maintenance, training for personnel, and potential upgrades. It's wise to perform a total cost of ownership analysis, which encompasses all potential costs over the equipment's lifecycle. Additionally, consider financing options that may allow for more flexibility in managing cash flow, ensuring that your investment in electronic assembly equipment enhances productivity without straining your budgetary constraints. Balancing the immediate financial outlay with the long-term benefits will ultimately support more strategic decision-making in your investment process.